Low pressure die casting (LPDC)

Alteams’s low pressure die casting (LPDC) produces high quality, lightweight aluminium parts optimised for performance, reliability, and industrial applications. At our headquarters in Laihia (Finland) we offer LPDC service with a dedicated team ready to support your project every step of the way.

What is LPDC ?

Low Pressure Die Casting (LPDC) is a manufacturing process used to make strong, precise aluminium parts with excellent mechanical properties.

The molten aluminium is pushed upwards into the die with low pressure. The mould is filled up slowly, which ensures the solidity of the part with no unwanted porosity. After solidification, the casting is removed from the mould, trimmed to eliminate excess aluminium, and then inspected.

When is LPDC used?

LPDC is a competitive casting method when the production quantity is relatively small or when heat treatment is needed to improve the mechanical properties.

- Medium to high-volume production → When you need consistent parts but don’t require hundreds of thousands of parts.

- Parts needing higher strength → Ideal for components that require lower porosity and better mechanical properties.

- Thicker or intricate sections → Works well for designs that HPDC might have challenges.

- Good surface finish required → Suitable for parts where quality appearance and minimal machining are desired.

Why is LPDC used?

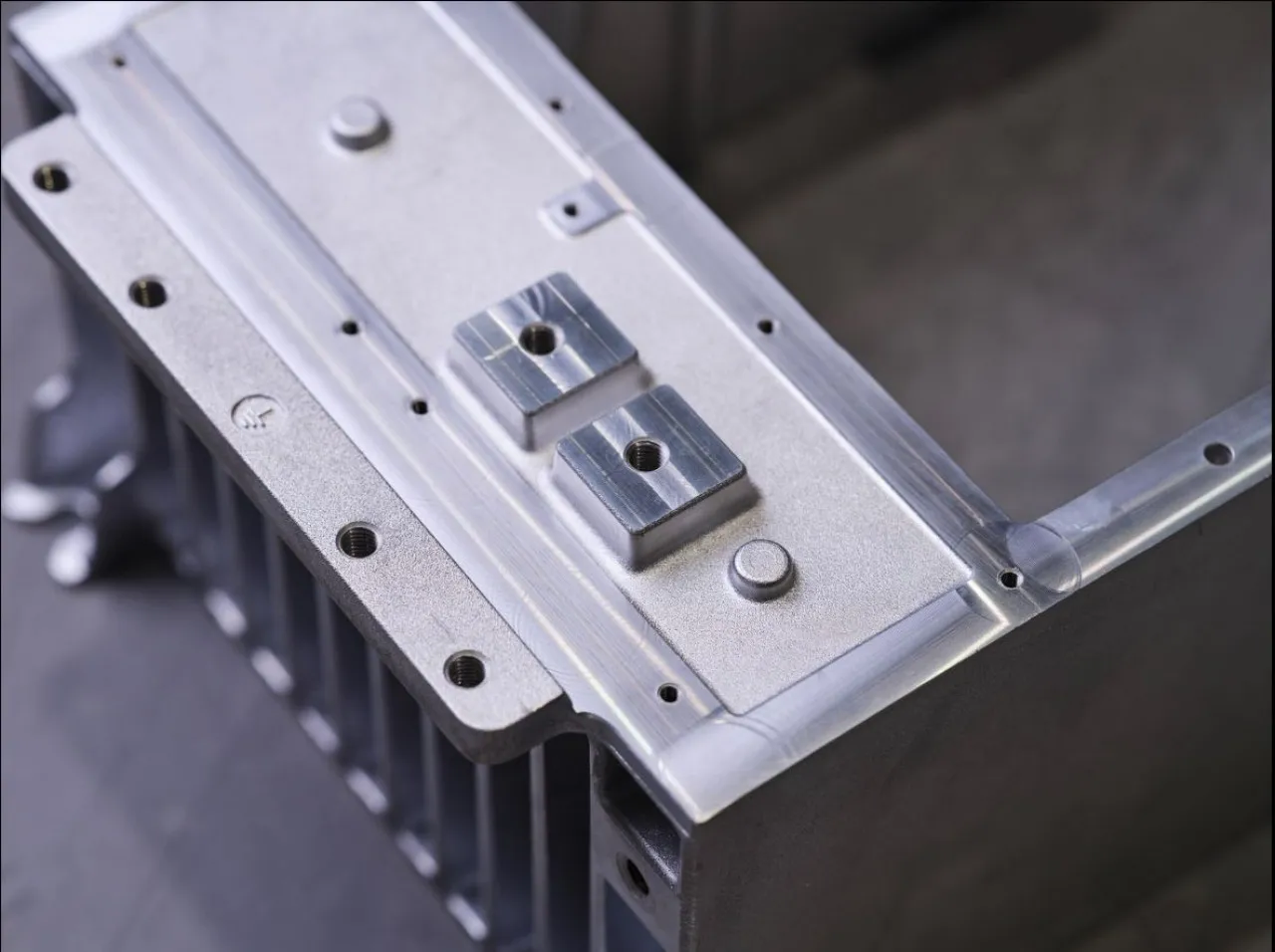

- High-quality parts with fewer defects → Low pressure reduces porosity and turbulence.

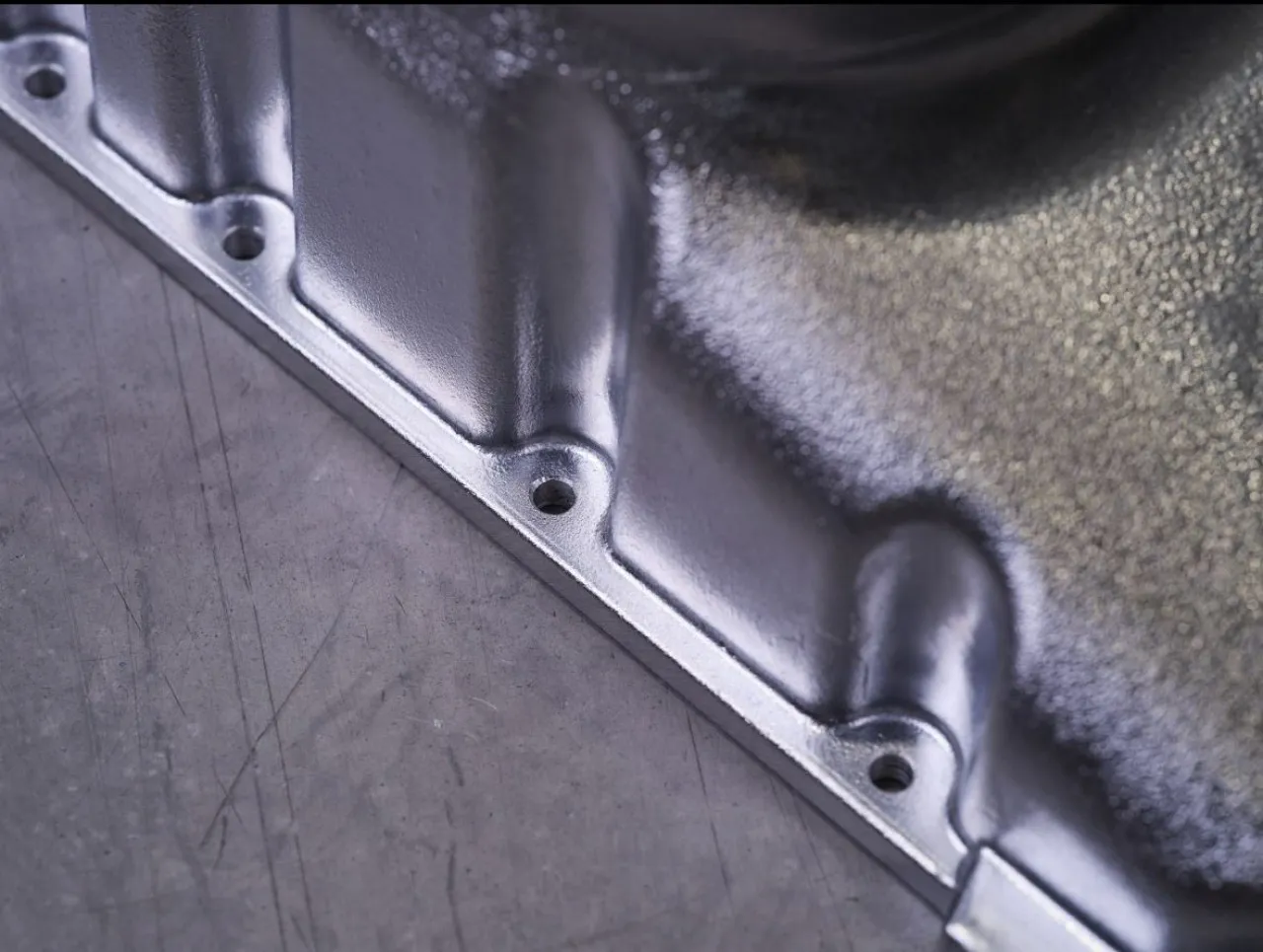

- Good surface finish and dimensional accuracy → Smooth, precise castings with minimal finishing

- Can produce thicker parts → Ideal for complex and larger designs.

- Reliable and consistent → Ensures repeatable results for medium- to high-volume production.

Where is LPDC used?

- Automotive: wheels, suspension components (control arms, knuckles), engine components (cylinder heads, cam covers) → high integrity, low porosity, and strong structural performance.

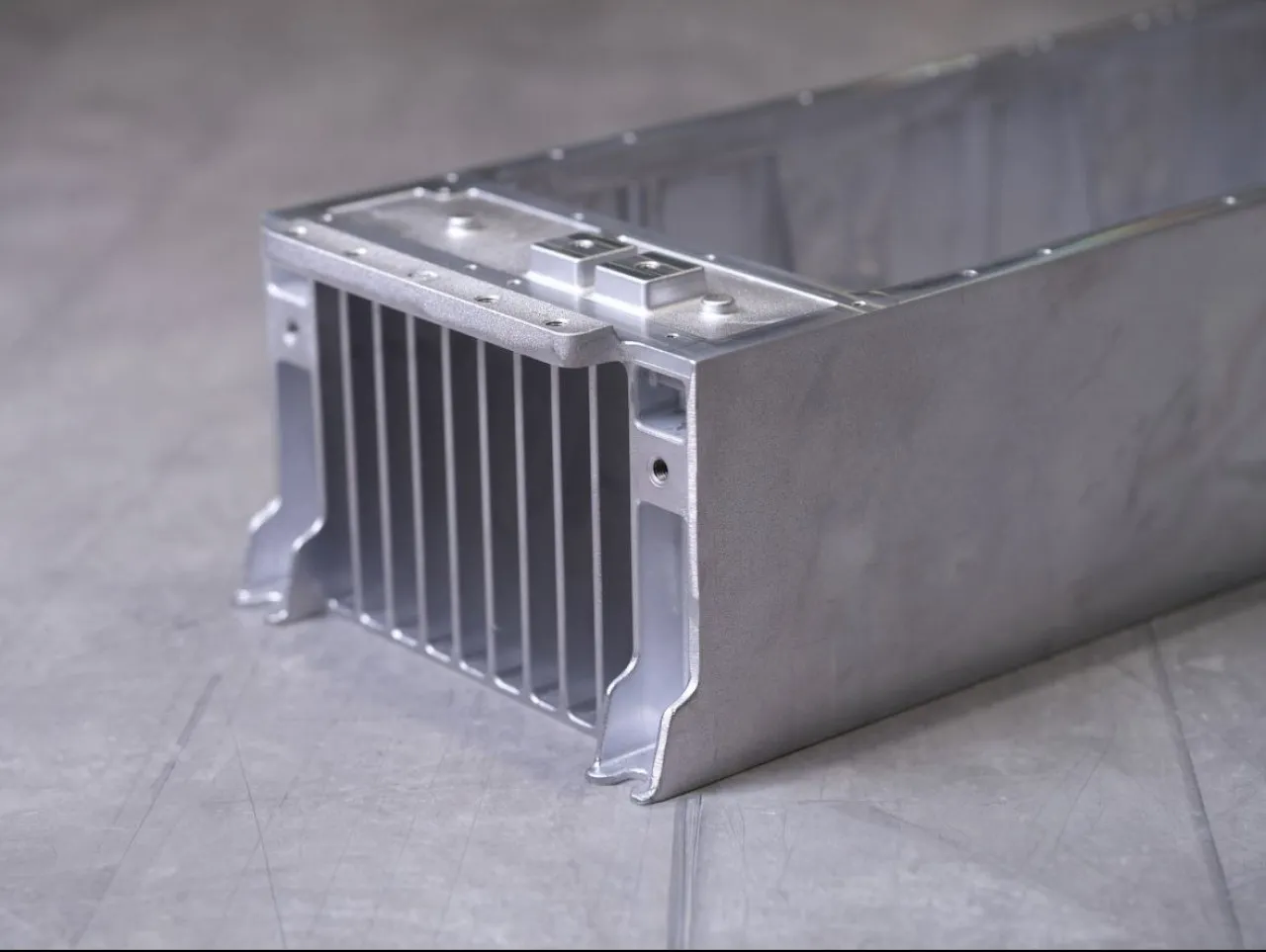

- E-mobility / Powertrain: motor housings, inverter housings, battery system structures → dimensionally stable, leak-tight, and thermally efficient.

- Industrial Machinery: pump housings, compressor bodies, hydraulic components → robust, pressure-tight, and durable.

FAQs

Explore More Casting Solutions at Alteams

Looking for the perfect manufacturing process for your project?

At Alteams, we specialize in High Pressure Die Casting (HPDC), Low Pressure Die Casting (LPDC), and Sand Casting — each tailored to different production volumes, part complexity, and surface finish requirements.