Pressure die casting enables a series of high volume manufacturing. This can be combined with new technologies to produce complex forms such as liquid cooled housing or precision placed heat conducting elements. As one of these new generation technologies, friction stir welding helps combine the best aspects of different materials and manufacturing processes.

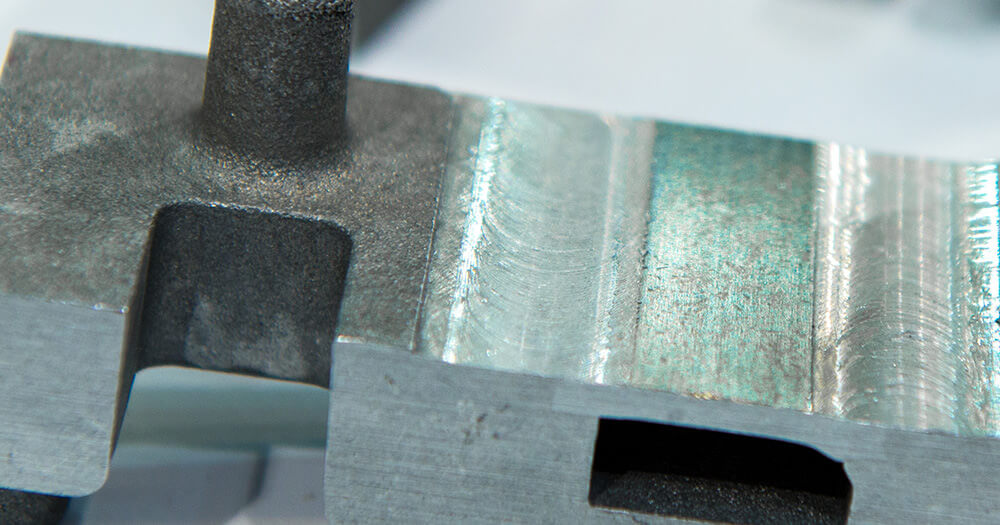

Friction stir welding (FSW) is a method that joins two pieces of metal together at a lower than typical temperature using a combination of pressure and mechanical manipulation. This creates a very strong seam between the pieces, effectively making them a single piece with great durability. The added possibility is, that the technique can be used to combine two different metals together, such as aluminium and copper. Hannu Kosonen, Development Engineer at Alteams states:

We’ve been experimenting with a lot of different materials and applications for FSW, and so far, all the material that we’ve tried can be joined using this technique. The experience and ideas we have collected gives us the tools and solutions for helping our customers update their existing products or design new ones to become more efficient with improved manufacturability.

A typical application for FSW could be a liquid cooled housing for power electronics. In this case, the frame of housing with the liquid cooling channels and the lid are die-cast separately and joined together by FSW. The possibilities, however, go far beyond that. When designing the complete product, FSW allows the designer to place material with higher heat conductivity such as pure aluminium in key places where the highest heat is generated. In this case, the frame is once again die cast, but the cooling elements are joined in place by FSW in addition to the top. Hannu Kosonen claims:

FSW is an interesting possibility for product designers. It can be used as a drop-in replacement for manufacturing structures where for example a lid with seal is screwed on top of a frame, making the manufacturing faster and the resulting product stronger. Once the effectiveness of making products this way is seen by the manufacturer, the next generation products can be designed with greater freedom.

Alteams has been testing a wide variety of applications together with our customers and partners. You can see our demo products presenting some of the possibilities of the technology for different applications at Euroguss 2018 exhibition. Our experts can show you how and why FSW was used in these applications. They can help you plan how to incorporate FSW into your processes and benefit from the technique.

Learn more about how your product design and manufacturing can benefit from FSW