Articles

17.01.2022 | Articles

Alteams Hitech Tools (AHT)

To meet growing demand for Telecom industry customers, Alteams founded Alteams Hitech Tools (AHT) in…

15.11.2019 | Articles

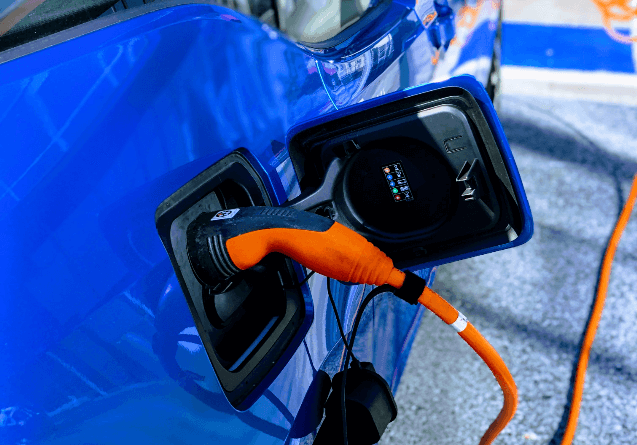

Automotive – Certifications ensure quality promise to customers

The automotive electric power line components are made with quality: Auto industry IATF16949

Operating certifications…

06.06.2019 | Articles

Aluminium casting method comparison – Pros and cons of different casting methods for aluminium parts

Aluminium is a great material for producing metal parts, whether you have an entirely new…

15.04.2019 | Articles

A three-step guide to successful prototyping for efficient casting and mass production

Ensuring the quality of a product before mass production starts from prototyping. It does not…

27.06.2018 | Articles

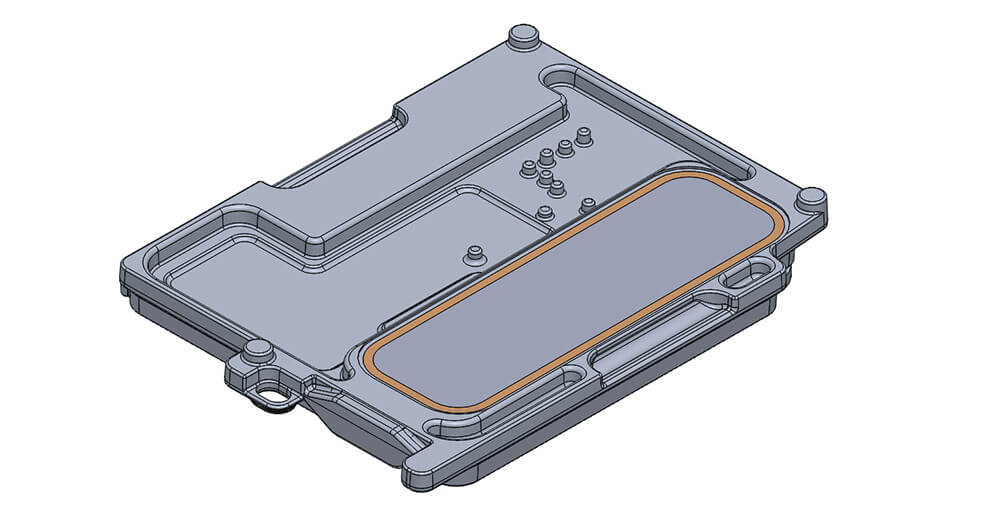

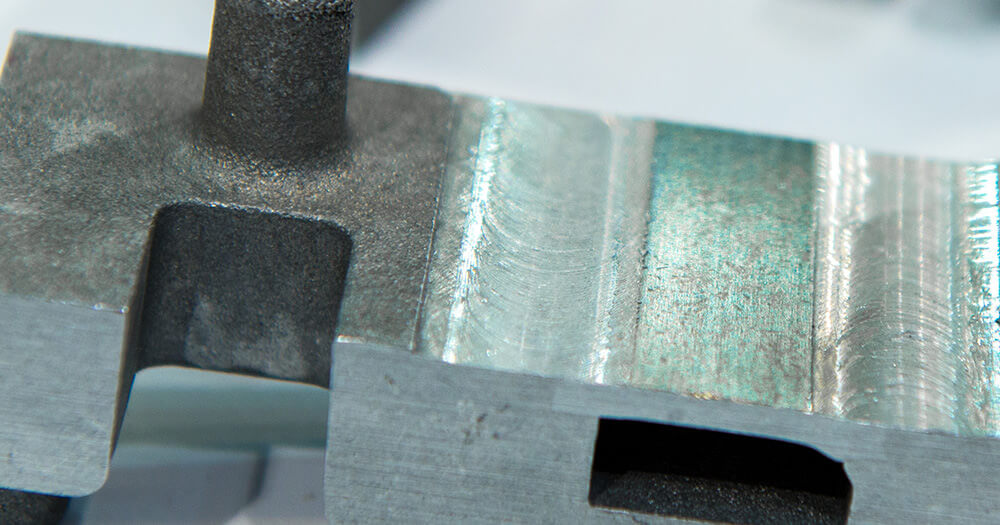

Friction stir welding opens up new business opportunities and manufacturing methods for cooling solutions

In power electronics sector, a new generation of powerful power packs creates a need for more effective cooling solutions. Alteams' product development team is committed to tackling the challenge!

27.06.2018 | Articles

The correct aluminium alloy can double the lifecycle of electrical components in casings

The HTC Aluminum Alloy is remarkable for its thermal conductivity properties. It is lightweight and ideal for complex casting forms. This alloy is created from the customer needs that answers challenges created by waste heat affecting component lifecycle, durability and maintenance of components.

27.06.2018 | Articles

Friction stir welding expands the design boundaries for products requiring multiple pieces and materials in one product

Pressure die casting enables series of high volume manufacturing. As one of these new generation technologies, friction stir welding helps combine the best aspects of different materials and manufacturing processes.